Inspection Products

Protecting Your Brand is Our Mission

Established in 2007, ENOS Engineering is a leading provider of inline real-time production inspection systems for the beverage, beer, wine, water, juice, sports drinks, liquor, pharmaceutical, cosmetic, household product and pet food industries.

ENOS Multi Barrier Technology System

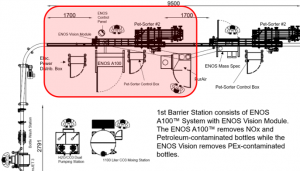

ENOS A100 “Sniffer” System which is described as a vapor analysis system designed to detect and remove consumer returned contaminated plastic Polyethylene Terephthalate (PET) refillable soft drink bottles from refilling (RefPet or PRB) lines.

Upon return of the reusable PET bottles, they are washed and refilled. Prior to refilling, these bottles are inspected for consumer added contaminants. If a foreign substance is detected, the bottles are automatically removed from the production line and destroyed. The non-contaminated bottles continue on to be washed, cleaned, and refilled. The ENOS A100 “Multi-Barrier System” is the product designed to detect and reject these contaminated bottles as they are returned for refilling.

ENOS Sniffer and Multi-Barrier Technology

- Reduction of Consumer Complaints protects brand value

- Strong gasoline, NOx, and PEx contaminated bottles are removed from the line prior to inspection by the Mass Spectrometer, allowing optimal final inspection prior to the bottle washer

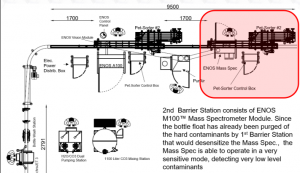

- ENOS Mass Spectrometer Module installed downstream of the ENOS A100™ and ENOS Vision Module

- Savings from reduced false rejects

Click on video arrow below to view how our Multi Barrier System works:

ENOS Sniffer Multi-Barrier Technology

1st Barrier Station ENOS A100 System

2nd Barrier Station ENOS Mass Spectrometer

ENOS Sniffer Multi-Barrier Technology